Watch enthusiasts know what an escapement is. The watchmaking dictionary defines it as the power supply system of the watch movement. Omega proudly touts its watches as devices equipped with the Co-axial escapement. It sounds great and all but what is the Co-axial escapement?

This blog, in its entirety, will be dedicated to making you understand what Omega’s coveted Co-axial escapement really is. Let’s begin.

What Is The Co-Axial Escapement?

The Haute Horlogerie world is like a mystery box sometimes. You do not know what innovation will come out next. The industry has its own ways of surprising you with the most fascinating objects and technologies. When it comes to innovation on an industrial level, it is kind of rare. For example, take the Lever (Anchor) Escapement which is used by most of the mechanical watchmakers today. It was invented back in the late 1700s. The automotive industry has a similar story with the internal combustion engine but that’s a tale for another day.

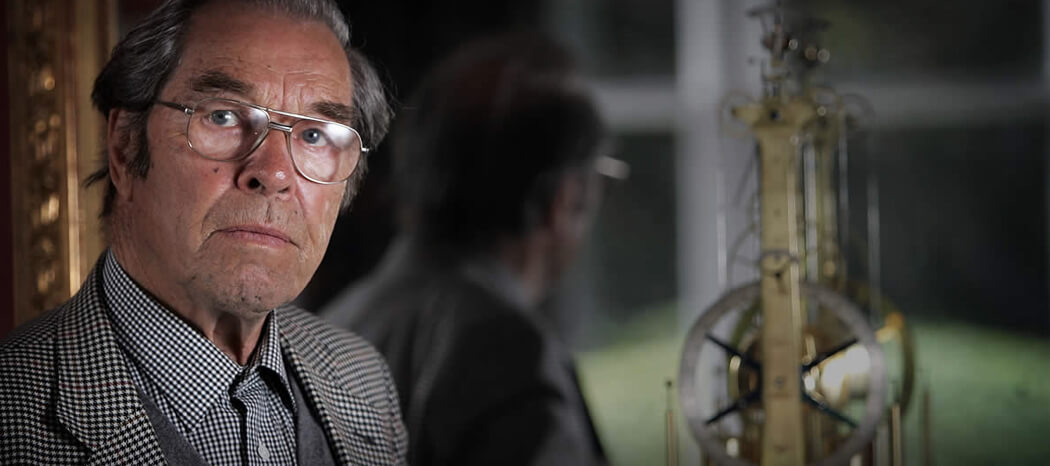

There’s one exception, though. When George Daniels created the Co-axial Escapement in the 1970s, little did he know what he was truly doing. What he did was more than simply making a new escapement. He challenged the widely accepted norm of a lever escapement and dared to create a new normal. That kind of action needs a vision.

The Escapement Explained

You see, the escapement is an essential part of a watch movement. It is practically the heart of the whole ensemble. The escapement decides at what pace the energy is to be released from the mainspring and relayed on to the oscillator. It is highly critical in terms of the luxury watches function.

George Daniels’ Ordeal

At the time George Daniels visited Switzerland to present his invention, the Swiss watch industry was undergoing a radical change thanks to the Quartz Crisis. It takes no genius to guess the result. He failed, repeatedly.

As far as the records go, the first time a wristwatch was seen with a Co-axial escapement, it was between 1974 and 1975. He fitted the new escapement inside a Calibre 1045 of his own Omega Speedmaster Mark 4.5. How badass is that?

After a couple of prototypes, Daniels finally saw a breakthrough with the help of Nikolas G. Hayek, the Chairman of the Swatch Group, Omega’s parent company and Swiss Haute Horlogerie elite.

How Does It Work?

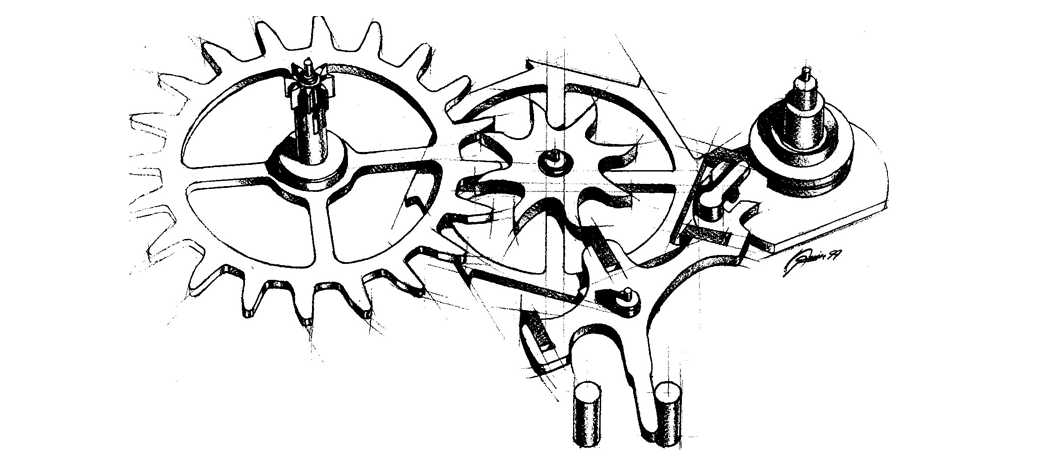

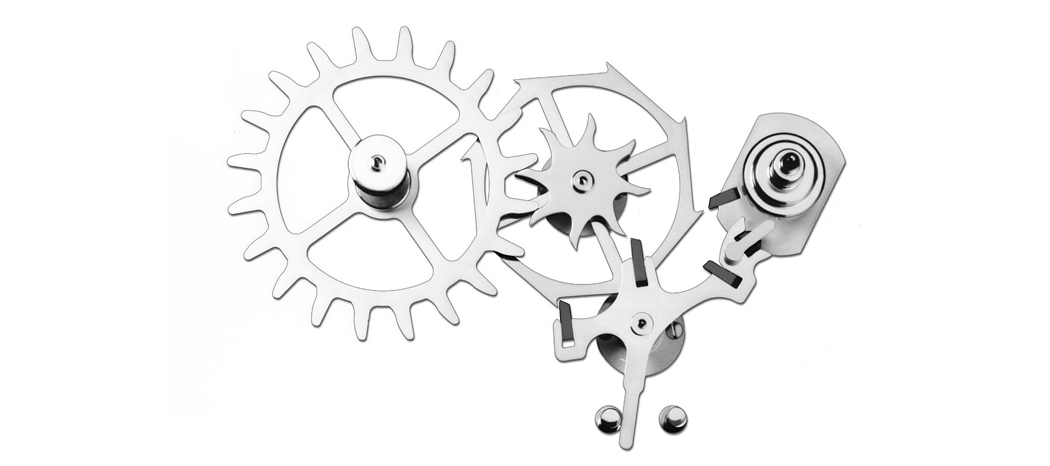

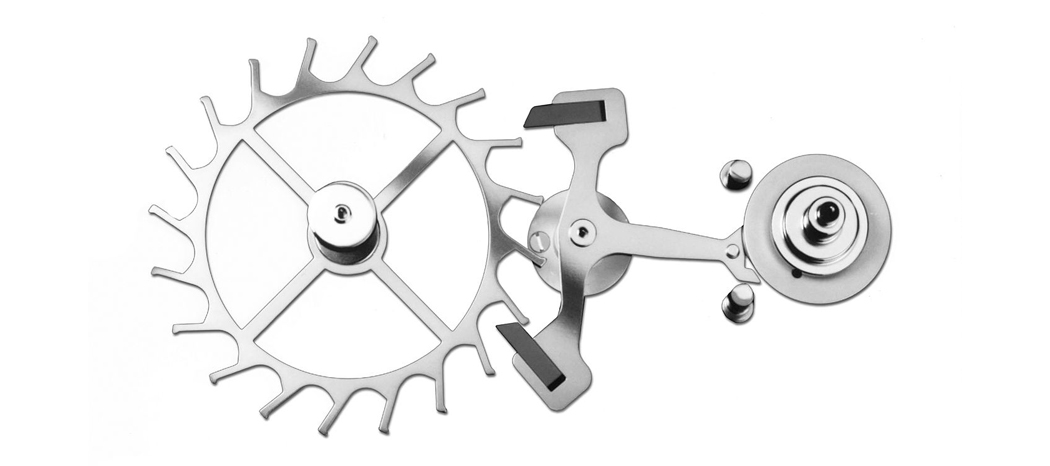

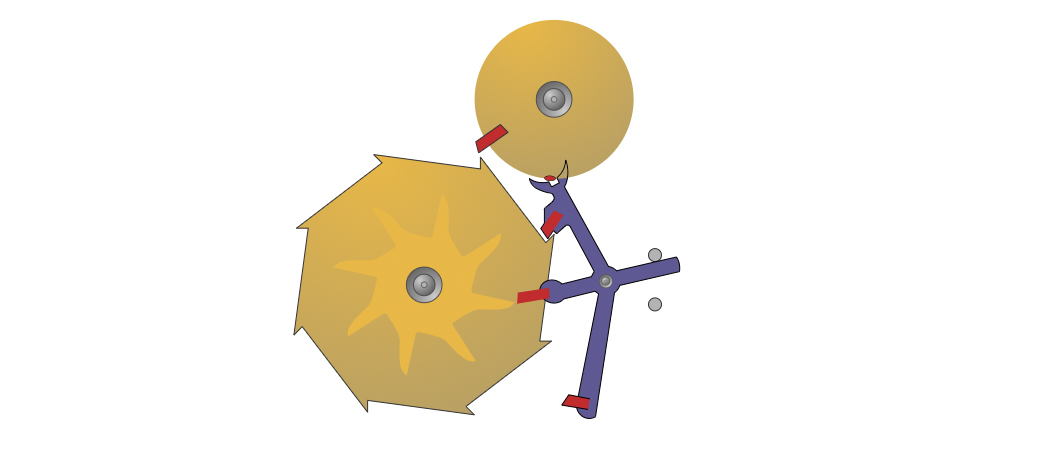

The Co-axial escapement operates through a system of three pallets that’s separates the locking feature from the impulse. This is done via a pushing action, instead of the sliding action as seen in the traditional Swiss lever escapement. The automatically results in better mechanical efficiency. In essence, the Co-axial escapement gets rid of all movements that cause friction. Theoretically, this directly results in superior precision and longer intervals between servicing.

The Omega Calibre 2500 was the first mechanical movement with the Co-axial escapement to be put to commercial production. It was launched in the market in 1999 in the Omega De Ville. This was, as they say, only the beginning. The watchmaker has since then introduced this technology to all its watches. The Speedmaster Moonwatch was the only exception until 2020. In 2021, Omega finally introduced the Co-axial escapement in the legendary timepiece, making all its watches equipped with the impressive piece horological tech.

The Calibre 2500 was actually a modified ETA movement. Omega shipped the ETA 2892 along with a Co-axial escapement. In 2003, however, the Omega Co-Axial chronograph had a Frederic Piguet mechanism. It wasn’t long before Omega began the production of its own movements in order to fully facilitate the co-axial technology.

Various Developments Made In The Co-Axial Escapement Over The Years

2007 – Co-Axial 8500

- Self-winding mechanism with the Co-Axial escapement

- Free sprung balance wheel

- Si14 silicon hairspring

- 2 barrels mounted in series

- Automatic winding in both directions

- Diameter 29 mm

- Power reserve 60 hours

- Frequency 25,200 VPH

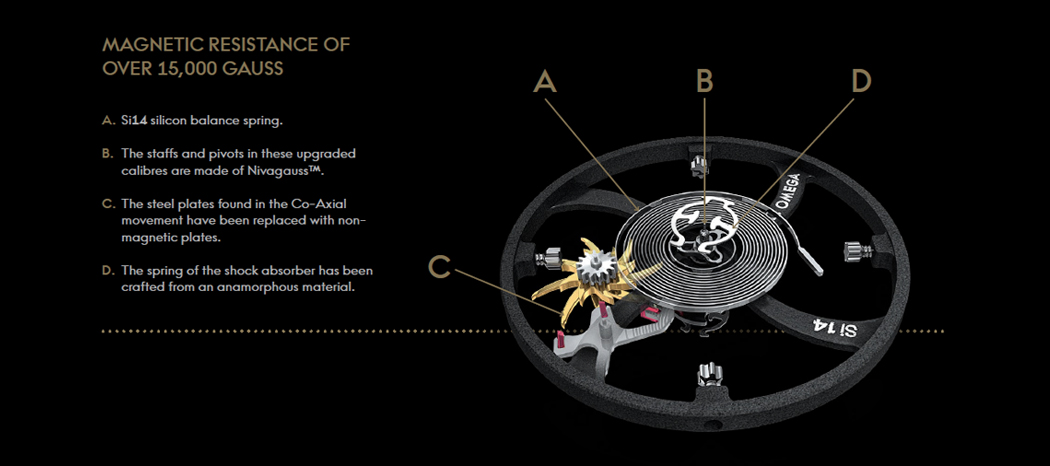

- The Calibre 8508 was based on this model. It was the first movement to be immune to magnetic fields of up to 15,000 gausses. The Calibre 8900/1 Master Chronometer, the watchmaker’s first movement to have the METAS certification, was also based on this model.

2008 Co-Axial 8520/1

- Self-winding movement with Co-Axial escapement

- Free sprung balance wheel

- Si14 silicon hairspring

- Automatic winding in both directions

- Diameter 20 mm

- Power reserve 50 hours

- Frequency 25,200 VPH

2011 Co-Axial 9300/1 Chronograph

- Self-winding movement with Co-Axial escapement

- Free sprung balance wheel

- Si14 silicon hairspring

- 2 barrels mounted in series

- Automatic winding in both directions

- Column-wheel chronograph

- Vertical clutch

- Diameter 32 mm

- Power Reserve 60 hours

- Frequency 28,800 VPH

- The Omega Calibre 9900 with METAS certification is based on this model

2016 Co-Axial 8801/8800

- Self-winding movement with Co-Axial escapement

- Free sprung balance wheel

- Si14 silicon hairspring

- Automatic winding in both directions

- Diameter 26 mm

- Power Reserve 55 hours

- Frequency 25,200 VPH

2019 Co-Axial 3861

- Hand-wound chronograph movement with Co-Axial escapement

- Free sprung balance wheel

- Si14 silicon hairspring

- Based on the Omega 1861 and Lemania 1873 blueprint

- Diameter 27 mm

- Power Reserve 50 hours

- Frequency 21,600 VPH

Deconstructing Omega’s Co-Axial Escapement

- Silicon

Omega uses silicon for the balance spring. The idea behind this is pretty simply. Omega wanted to utilize the anti-magnetic properties of silicon. Silicon is also great for precision manufacturing geometric shaping.

- Anti-Magnetic Components

The staff and pivots are made of NivaGauss, an anti-magnetic material developed by Omega.

- Sedna Gold

This is a gold alloy that merges gold, copper, and palladium.

- Barrels

The barrels inside a Co-axial movement are coated with DLC for reduced friction.

Recent Posts

Recent Comments

Archives